.jpg) DURKEE at AHR Expo 2026 – Non-Rigid Air Duct & Thermal Insulation Solutions

DURKEE at AHR Expo 2026 – Non-Rigid Air Duct & Thermal Insulation Solutions

BOE Vietnam Factory: Non-rigid Air Duct Solutions for Electronic Industry

BOE Vietnam Factory: Non-rigid Air Duct Solutions for Electronic Industry

Why Fabric Air Ducts Are the Preferred Choice for Ventilation in Large Spaces

Why Fabric Air Ducts Are the Preferred Choice for Ventilation in Large Spaces

2024-06-19

The 17th SNEC International Photovoltaic and Smart Energy Conference was held in Shanghai, Durkee made an appearance, showcasing the flexible ducting system integrated solutions. We have presented multiple technologies in depth to help our top users create low-carbon factories featuring "Green, Energy-saving, and Carbon-reducing." As a global leading brand in the HAVC/R industry, Durkduct features multiple advantages in the photovoltaic industry compared with traditional GI ducts.

As in the silicon material manufacturing factory, the workshop normally has a single-ceiling steel structure. There are requirements for a class 10,000 or 100,000 cleanroom, with a constant temperature of 23±2°C, and a requirement for a slight positive pressure air supply. The traditional GI duct solutions always come along with higher air leakage, bigger energy consumption, longer installation periods, and higher costs. As for the integrated solution of the Durkduct fabric air duct system, the flexible ducts are used as transmission ducts in the ceiling design. These ducts will be connected to high-efficiency air filters for air dispersion. Through the layout of ducts with equal resistance and the use of unique fiber fabric flow control dampers inside the ducts, different branch ducts in a complex system will receive an equal volume of air distribution.

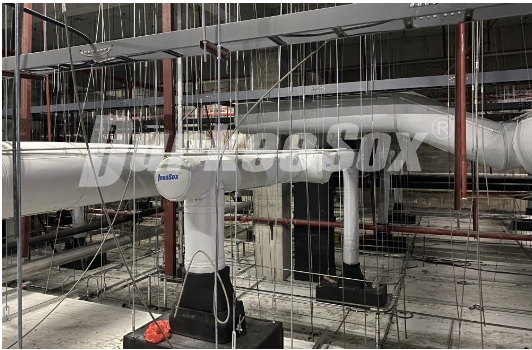

When it comes to the photovoltaic battery workshop, it’s usually a multi-layer ceiling steel structure. The main workshop requires a class 10,000 cleanroom, with some areas requiring a class 1,000 cleanroom. Additionally, due to differences in battery types, the cleanliness requirements may vary slightly (transitioning between class 10,000 and class 1,000).

The integrated solution of Durkduct textile ducting system in the multi-layer ceiling: Within the static pressure layer, the main transmission duct uses Nanosox, and the branch ducts use Fibersox, the fabric air duct (if the branch duct length exceeds over 50 meters, Insusox, the pre-insulated ducting are used). Through perforated ducting, the air can be delivered to the air supply inter-layer, and the ceiling inter-layer is equipped with FFU (Fan Filter Units) to supply the air to the production workshop. The Flexible Air Duct System adapts STU (Sector Tridimensional and Uniform Air Dispersion ) Technology. Through axially uniform perforations, and radially linear, a fan-shaped three-dimensional airflow is formed, bringing an excellent airflow effect for ceiling inter-layer.

In the future, Durkduct will continue to expand the market of the photovoltaic industry. Through technological innovation and high-quality service, we are committed to providing HVAC ducting system solutions for zero-carbon factories in the photovoltaic industry. We aim to promote high standards, high efficiency, and high-quality upgrades and development within the industry and the supply chain. Our ongoing contributions will help achieve green, energy-saving, and carbon-reducing goals in building projects.