.jpg) DURKEE at AHR Expo 2026 – Non-Rigid Air Duct & Thermal Insulation Solutions

DURKEE at AHR Expo 2026 – Non-Rigid Air Duct & Thermal Insulation Solutions

BOE Vietnam Factory: Non-rigid Air Duct Solutions for Electronic Industry

BOE Vietnam Factory: Non-rigid Air Duct Solutions for Electronic Industry

Why Fabric Air Ducts Are the Preferred Choice for Ventilation in Large Spaces

Why Fabric Air Ducts Are the Preferred Choice for Ventilation in Large Spaces

2024-05-30

Tesla's Shanghai Megafactory is expected to go into production in the first quarter of 2025, with Megapack production of up to 10,000 units per year and nearly 40 GWh of energy storage. Megapacks are meant to be used to help stabilize energy grids. Each unit can store enough energy on average to power 3,600 homes for one hour. They are designed to be deployed by utilities and power stations.

Durkee has foreseen the future trend of the new energy battery market, we have innovated the flexible duct integrated solution to meet multiple needs of different manufacturing scenarios. Back in 2016, Durkee stood out among various international competitors and applied the fabric ducting system to Tesla’s Gigafactory in Nevada, USA, and some other benchmark projects such as CATL new energy module workshop and BTR Cathode Material Factory.

The material distribution center of the CATL factory building has a floor height of 8.3 meters with a light-steel structure and an air-conditioning area of 10,472 square meters. The design uses Nanosox fiber fabric air ducts for air supply, and the air ducts are evenly arranged at a height of 6 meters. The continuous diameter reduction makes excellent airflow organization along the straight ducts, effectively reducing the temperature rise in the long ducts. The extremely lightweight Durkduct fabric duct system features a simple and pleasing look and has no extra burdening requirements for the light-steel structure.

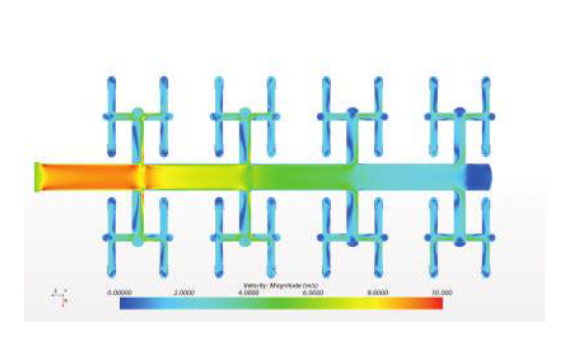

In the BTR factory, the building height is 23 meters, and the total area is about 46,000 square meters, making it a large-space steel structure. Considering the high floor height of the building, Insusox, the pre-insulated duct system with lower air leakage is designed in the suspended ceiling as transmission air ducts to lessen the high-altitude energy loss. The special design of oblate main ducts + round branch ducts saves much material and costs compared with the traditional rectangular air duct solution. The design adopts IPBA (Inner Pressure Balanced Adjustment) technology in the pre-insulated air duct so that branch ducts at different positions in the complex system can obtain equal air volume distribution.

We keep focusing on flexible ducting innovation to offer more effective and environment-friendly air dispersion solutions, promoting the sustainable development of the new energy battery industry. Durkduct Fabric Air Ducting System features in uniform air supply, lower air leakage, energy-saving, no dust-generating, no harmful gas release, easy installation, high-cost efficiency, long lifespan, and user-friendly maintenance. After more than a decade of application and promotion in the global and domestic markets, Durkduct hvac duct manufacturer Flexible Air Duct System is accelerating the updating and replacement of the traditional GI ducts in the new energy battery industry.