.jpg) DURKEE at AHR Expo 2026 – Non-Rigid Air Duct & Thermal Insulation Solutions

DURKEE at AHR Expo 2026 – Non-Rigid Air Duct & Thermal Insulation Solutions

BOE Vietnam Factory: Non-rigid Air Duct Solutions for Electronic Industry

BOE Vietnam Factory: Non-rigid Air Duct Solutions for Electronic Industry

Why Fabric Air Ducts Are the Preferred Choice for Ventilation in Large Spaces

Why Fabric Air Ducts Are the Preferred Choice for Ventilation in Large Spaces

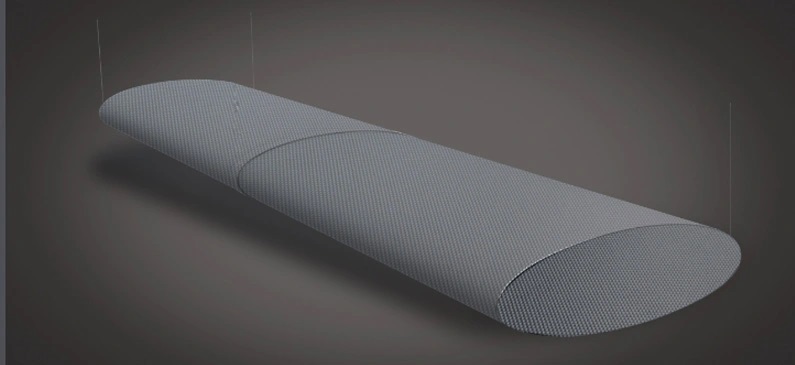

In the HVAC/R industry, air duct systems play a decisive role in shaping indoor air quality, thermal comfort, and energy efficiency. For decades, Metal Ductwork has been the standard choice, but it often brings challenges such as heavy weight, complicated installation, condensation issues, and higher maintenance costs. As buildings demand smarter and greener solutions, non-metallic air duct systems have emerged as a superior alternative. By combining advanced fiber materials with innovative design, these ducts offer lightweight, flexible, and energy-efficient solutions that meet the requirements of modern industrial, commercial, and public spaces.

Durkee®, a multi-national high-tech enterprise, has been a pioneer in promoting this transition. Through its renowned brand Durkduct®, the company has consistently delivered fabric ducting systems that redefine the standards of performance, durability, and environmental responsibility in the HVAC sector.

One of the most significant advantages of non-metallic air duct systems lies in their lightweight nature. Traditional Metal Ductwork requires heavy-duty suspension structures, large lifting equipment, and labor-intensive assembly. This often extends construction timelines and adds considerable cost to both new projects and retrofits. In contrast, non-metallic solutions are only a fraction of the weight, enabling easy handling, modular installation, and faster project delivery. For high spaces such as sports arenas, warehouses, or exhibition centers, this means reduced structural load, simplified logistics, and safer construction processes.

In addition, the adaptability of non-metallic materials from the professional fabric duct manufacturers allows for flexible design layouts that can adjust to the architectural complexities of large or irregular spaces. Whether in new constructions or renovations, their modularity ensures that the ducts can be adjusted or relocated to meet evolving needs without compromising airflow performance.

A critical challenge in HVAC systems, particularly within large spaces, is ensuring uniform air distribution. Conventional Metal Ductwork often creates uneven airflow, resulting in hot and cold spots, drafts, or zones of poor ventilation. Non-metallic air duct systems overcome this issue through advanced permeable fabric structures and micro-perforation technology, which allow air to disperse evenly across the entire surface.

This creates a gentle, draft-free environment where air quality and comfort are optimized for occupants. From indoor sports venues to manufacturing facilities, the result is a more consistent and stable indoor climate that enhances both performance and user experience.

Feature | Non-Metallic Air Duct | Metal Ductwork |

Weight | Extremely lightweight, easy to handle | Heavy, requires strong support structures |

Installation Time | Fast modular installation, minimal equipment | Labor-intensive and time-consuming |

Air Distribution | Uniform, draft-free airflow | Prone to uneven airflow and hot/cold spots |

Maintenance & Cleaning | Easy to detach, wash, or replace | Difficult to clean, dust and bacteria accumulate |

Condensation Resistance | Naturally resists condensation and dripping | High risk of condensation in humid conditions |

This comparison highlights why industries are increasingly choosing non-metallic air ducts. They not only reduce the total cost of ownership but also enhance operational efficiency and indoor environmental quality.

Another key benefit of non-metallic systems is their hygiene-friendly design. Over time, Metal Ductwork can accumulate dust, dirt, and microbial growth, which requires costly and disruptive cleaning processes. Non-metallic air ducts, however, can be easily removed, washed, and reinstalled without complex equipment. Their breathable fabric also helps reduce moisture buildup, preventing mold or bacterial growth. This makes them an ideal solution for environments where cleanliness and air purity are paramount, such as sports facilities, food processing plants, and healthcare-related spaces.

In terms of longevity, the advanced fabrics used in Durkduct® products are engineered to withstand wear, UV exposure, and temperature variations, ensuring long-term performance while minimizing maintenance interruptions.

As one of the world's leading fabric duct manufacturers, Durkeesox has set benchmarks for innovation and sustainability in HVAC/R. With more than 25 years of expertise, two modern manufacturing centers, and a presence across 36 countries, the company has earned recognition as the fastest-growing supplier of fabric air dispersion systems in Asia and beyond. Its membership in the United States Green Building Council (USGBC) further underscores its commitment to low-carbon, environmentally responsible solutions.

By leveraging its global experience and advanced production capabilities, Durkeesox continues to expand the application of non-metallic air duct systems worldwide. Through its dedication to innovation, quality certifications such as ISO9001 and UL standards, and its trusted brand Durkduct®, the company remains at the forefront of transforming the way air is distributed in high-performance spaces.